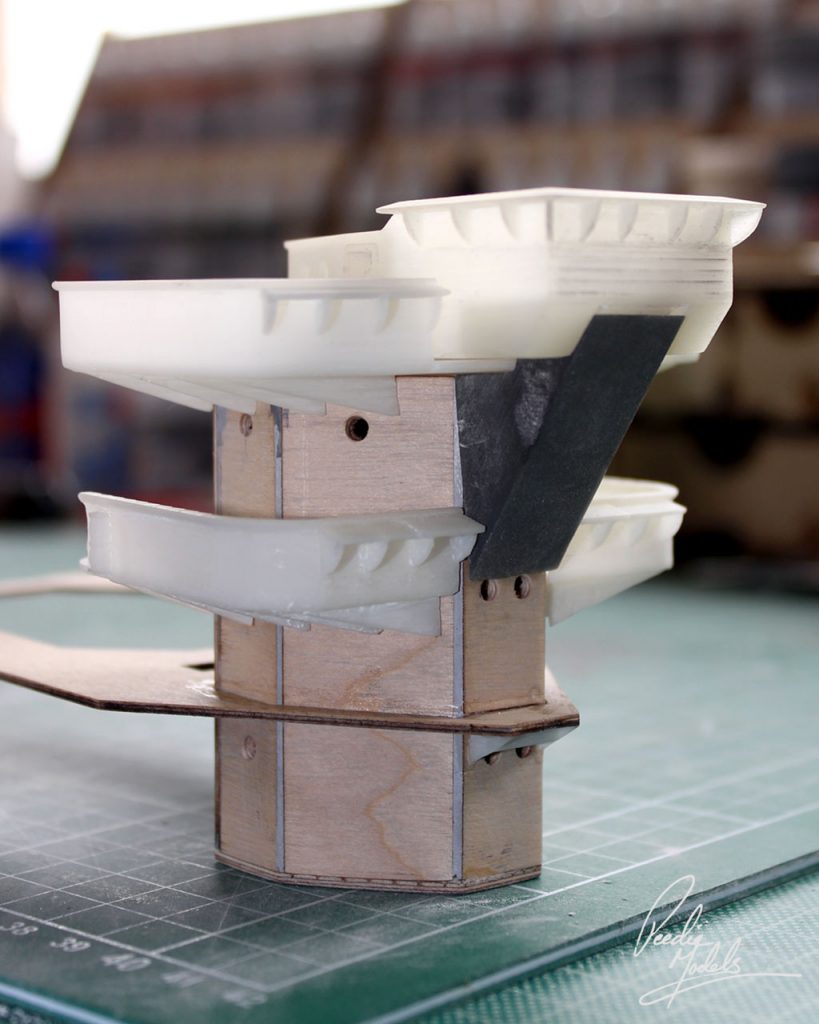

Now I have all the parts for the conning tower its time to start the test fitting them to ensure its a tight fit. A challenge I have is that all 3D printed parts can have slight differences in size, which can be down to the resin curing at different rates which becomes more noticeable when used with other materials as in the case with the laser cut ply main structure.

Its looking very good at this time with minor clean up and filling, so on to drilling the holes for the mast support then I can start the fixing process, well after drilling all the stanchion holes on the lower bridge as this could be a little tricky once fixed in place.